- #Autodesk moldflow insight how to

- #Autodesk moldflow insight android

- #Autodesk moldflow insight software

- #Autodesk moldflow insight download

eBooks are intended for single user use only. #Autodesk moldflow insight software

Dual monitors, tablet, or separate reader device is recommended to facilitate use of the eBook with the software throughout the course.  Access your eBook online from any Internet-connected device with a modern browser.

Access your eBook online from any Internet-connected device with a modern browser. #Autodesk moldflow insight android

Android Smart Phones & Tablets (requires Android 5.0 and higher). iPhone, iPod Touch, and iPad (requires iOS 11 or later). #Autodesk moldflow insight download

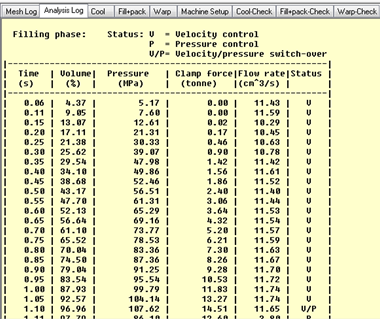

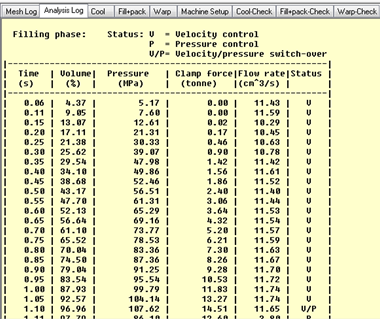

Download your eBook to your mobile phone or tablet and open it in the free VitalSource Bookshelf app. No Internet connection is required after you download your eBook to the VitalSource Bookshelf. Download your eBook to your personal computer and open it in the free VitalSource Bookshelf application. This format enables you to access your eBook in three ways. Prior mold analysis experience is not necessary.ĪSCENT eBooks are delivered through the VitalSource Bookshelf e-textbook platform. The practices and files included with this guide might not be compatible with prior versions. Access to the 2019 version of the software. Designing flow leaders and flow deflectors. Creating part models, feed systems, and cooling channels. Creating HTML, PowerPoint, and Word based reports of an analysis. Overview and working with thermoplastics and the injection molding process. Working with runners (designs, modeling, and balancing). Types, manipulation, and interpretation of results. Conducting and interpreting a molding window analysis. Gate placement guidelines and gate location analysis. Use flow charts to discuss optimization of filling, packing, and warpage of a part. Step through the general process for analysis projects. Complete a Cool, Fill + Pack + Warp analysis. Overall, the goal is to teach students to become more efficient at creating digital prototypes, running analyses, and interpreting the results of most of the analysis types available in the Autodesk Moldflow Insight software. In the Practice guide, students are provided with exercises to practice the workflows that have been discussed. #Autodesk moldflow insight how to

The Theory & Concepts guide discusses the theory, background, and workflows used in Autodesk Moldflow Insight to teach students how to apply Moldflow analysis techniques to their parts.

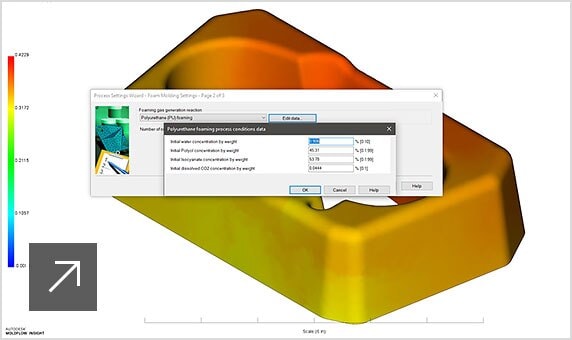

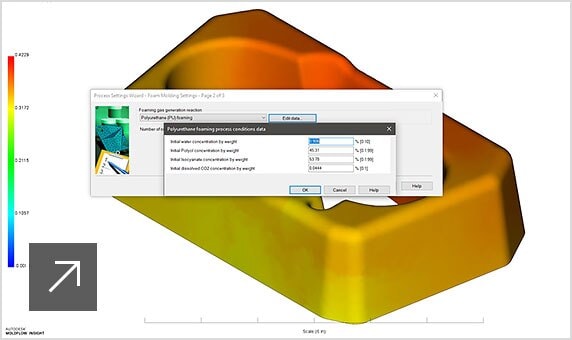

This result can be used to show the effect of gas concentration and bubble growth on the viscosity of the polymer.The Autodesk Moldflow Insight Fundamentals 2019 training material consists of two learning guides: Theory & Concepts, and Practice. Since the gas concentration changes over time, the viscosity of the polymer will change.

After the gas is injected, the viscosity decreases. The 3D viscosity result is more accurate than the fast algorithm or the finite difference algorithm because actual values are being determined at each node of the solid model.įor microcellular analyses, the presence of gas bubbles changes the viscosity of the polymer. The values calculated by the program are the actual viscosity values for the tetrahedral elements, or nodes and represent a real case injection molding scenario. The results are calculated from the viscosity distribution across the molten (above transition) part of the cavity.įor a Fill analysis using 3D analysis technology, viscosity is calculated for each tetrahedral element or node throughout the model. In general, as the temperature and shear rate that the polymer experiences both increase, the viscosity will decrease, indicating a greater ability to flow under a given applied pressure. The viscosity of polymers is dependant on temperature and shear rate.

0 kommentar(er)

0 kommentar(er)